Below are two oil analyses results. The one on the left is virgin Brad Penn 10w/40 semi-synthetic oil, straight from the bottle. Any new oil is going to have particulates, some oils will have more, some will have less, none will be absolutely pure.

The results on the right are from a Testarossa beginning December 2015. We installed the Gavarino bypass system on the Testarossa August 2016. Prior to installing the system, we conducted a particle count analysis in July 2016, which shows 111,089 of 4 micron particulates in 1ml of oil using a standard, stock filter.

After over a year and 3,250 miles of running the Gavarino bypass system on the Testarossa, we conducted another oil analysis. As the test results below indicate, we saw a significant reduction (108,896) of 4 micron particulates in 1ml of oil, practically a 98% improvement, which is consistent with the data provided to us by our filter supplier, Amsoil. Along with the test results, we have also included a chart that will help you interpret the ISO 4406 cleanliness codes and how that relates to understanding oil analysis results.

Oil analysis on the right is from a 1991 Testarossa.

Before bypass system installation it tested with a 24/21/11 ISO 4406 rating

After bypass system installation it tested with a 18/14/8 ISO 4406 rating

Before Installation After Installation

24 = 80,000 to 160,000 – 4 micron 18 = 1,300 to 2,500 – 4 micron

21 = 10,000 to 20,000 – 6 micron 14 = 80 to 160 – 6 micron

11 = 10 to 20 – 14 micron 8 = 1.3 to 2.5 – 14 micron

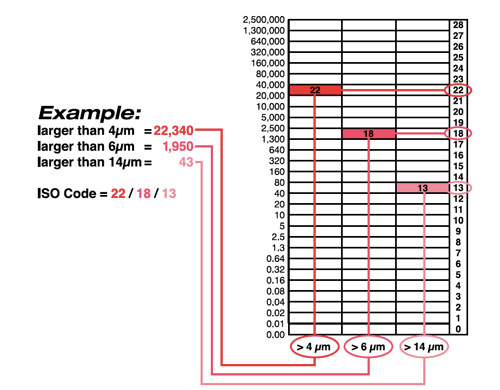

Understanding ISO Codes

Though particle counting is reported as an actual count of the number of particles (of a given size, per ml of fluid), most specifications and limits simply refer to ISO codes. The ISO codes, according to the ISO 4406:1999 standard, relate to only three different ranges of particles, ≥4 µm/≥6 µm/≥14 µm.

It should be noted that each range is equal to or greater than its designated micron rating, meaning that all particles counted in the ≥14 micron range will be included in the count for the ≥6 micron range, which in turn is included in the ≥4 micron range. As such, the ≥4 micron range is always the highest count, followed by the ≥6 micron range, then the ≥14 micron range.

To convert the particle count into an ISO code, please refer to the example on the right. The original particle count is in the right-hand table, and the ISO codes are in the left-hand table. For each progressively higher ISO code, both the quantity and range of particles doubles.

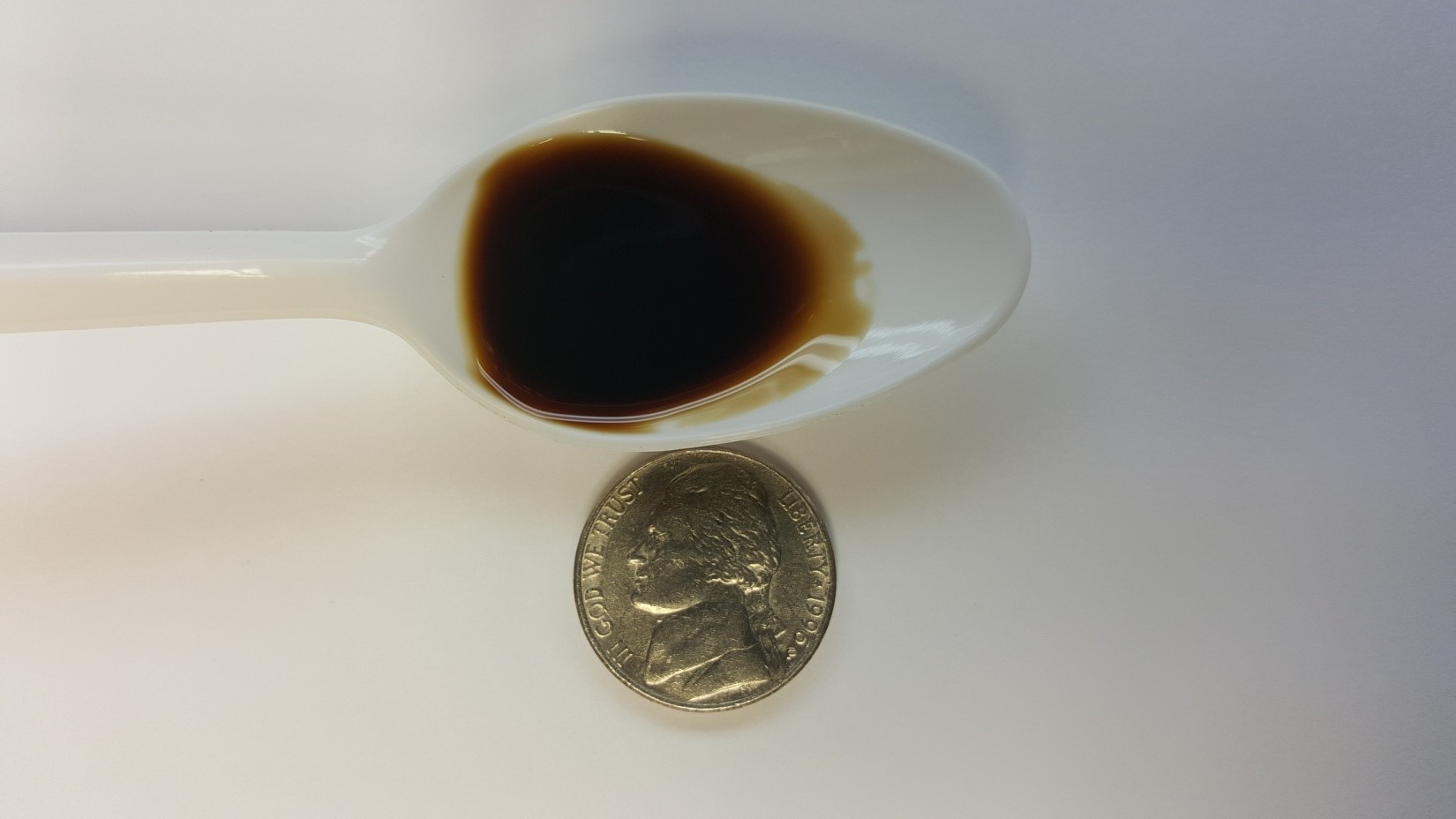

This Is How Much Oil Is Tested In An Analysis – 1ml

This Is How Much Oil Is Tested In An Analysis – 1ml

SAE paper 710813; “The use of good full flow filtration, combined with bypass oil filtration, will result in the extension of engine wear up to two to three times the wear life obtainable with only good full flow filtration”

Tribology International, 1991, pg. 329; “New oil right out of the can is not as good one might think but contains metallic and nonmetallic particles in various amounts”.

Fact No. 1: When engine oil is replaced, the new oil becomes dirty the moment the engine is started. This is because approximately 18% of the old oil remains in the engine. The 18% old oil instantly contaminates the ‘new’ oil.

Fact No. 2: Test results from engines equipped with full flow filter elements have shown that 4% of the oil drained from the engines was solid particles consisting of carbon, dirt and other particles.

Conclusion: Since used oil typically contains 4% solid abrasives then the following formula is used:

Average contaminate = Initial contaminate + final contaminate

In this case, 2% of the oil circulated to the engine during this period was dirt. By way of example, if an engine is driven 12,000 miles per year, in excess of 100,000 quarts weighs approximately 212,000 pounds or 106 tons. If 2% of this is abrasive solids, then over 2 tons of solids are passing through the engine per year.

Tribology International Facts Conclusions dissected for large sump oil systems and lower miles driven vehicles

(Fact 1)

10 quart oil system

10 quarts = 320 ounces

18% of 320 oz. = 57.6 oz

57.6 oz = 1.8 quarts

1.8 quarts of dirty oil left in oiling system to mix in with “new” oil during oil change

(Fact 2 ) Simplify by dividing everything by 6

12,000 / 6 = 2000 miles driven

100,000 / 6 = 16,666.66 quarts oil passed thru engine

212,000 / 6 = 35,333 lbs. of particulates

2% of 35,333 lbs = 706.66 lbs of particulates

Using this formula 706.66 lbs. passed through engine and oiling system in 2000 miles

If 98.7% efficient oil bypass filtration system was used:

706.66 lbs – 98.7% = 9.18 lbs of particulates

Using this formula and a Gavarino Oil Bypass System only 9.18 lbs of particulates would have passed through engine and oiling system

*Tribology is the science of rubbing surfaces, from live cell friction to engine lubrication and seismology. As such tribology is truly multidisciplinary and this extraordinary breadth of scientific interest is reflected in Tribology International. Tribology International seeks to publish original research papers of the highest scientific quality to provide an archival resource for scientists from all backgrounds.

*SAE International is a global association of more than 128,000 engineers and related technical experts in the aerospace, automotive and commercial-vehicle industries. Our core competencies are life-long learning and voluntary consensus standards development.